Here is the recipe that I came up with, to use the hops harvested from the garden. Since I thought going with more of an IPA style beer would really highlight the fresh hops in the final beer.

Recipe:

- Pale Malt (2 row) UK – 11.5 lbs

- Caramel/Crystal Malt 40L – 1.5 lbs

- Cara-pils/Dextrin – 0.5 lbs

——

Total 13.5 lbs of grain

Yeast: Wyeast American Ale #1056 smack pack

1 tsp of Irish Moss added 15 mins before chiller was started

2 ½ tsp of Fermax Yeast Nutrient added to the Primary

Hop Additions:

1st addition – Centennial – 1 oz. – 60 mins

2nd addition – Cascade – 1 oz. – 30 mins

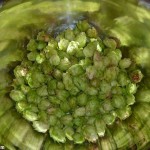

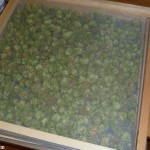

3rd addition – Centennial – 4 oz. Fresh – Secondary fermentor

6 gallons with O.G. of 1.046

In the primary for 7 days at which point it had a gravity of 1.022. Racked the batch to a secondary, and added 4 ounces of the fresh centennial hops. I then let in sit in the secondary for just a week short of two months. F.G. 1.012 and it was kegged and bottled (into about a half dozen bottles.) on October 7th, 2011.

Update January 10, 2012: Having now had a few pints from the keg (which I forced carbonated), I have to say that this is best beer that I’ve brewed to date. Is the beer a bit hoppy? You bet, but it’s not like I was surprised, since I did used 6 ounces (2 oz dried/4 oz fresh) of hops in the batch for a total IBU of ~63. My only gripe is that my brewhouse efficiency still totally sucks at the 60% range, which is a sorry state of affairs. But at this point, it’s just the cost of doing business for me.